HNC606T is our advanced and affordable system for CNC lathes and grinders. It adopts high-speed ARM processor (new industrial grade), large-scale filed programmable gate array (FPGA) technology, control circuit with multi-layer PCB printed circuit board. The system itself has a more compact and reasonable structure. It is equipped with high-integration chips and surface mount components, which brings better guarantee for system reliability and stability.

Its notable features include high-speed real-time control (maximum rapid traverse speed can reach 30m/min, maximum feed interpolation speed can reach 15m/min); high precision, 800*600 TFT LCD and brightness adjustable. It has overcome the longer service time and the disadvantage of display brightness varies according to the ambient temperature. It has English on-screen menu. Operations are very simple and convenient.

This is a two-coordinate linkage, open-loop CNC system. CNC is very common in lathe applications. It has powerful functions, rich commands, which can directly control the AC servo system. The programming codes comply with ISO international standard.

- Coordinate axes: There are 2 axes.

- Supports high-speed ARM/DSP/FPGA/hardware interpolation technology.

- Maximum speed: 60m/min, Feed speed: 0.01…30m/min.

- It has a USB interface.

- Supports internal RS232 communication.

- Memory for part program: 32M, no program number limit.

- You can program preloading for small line segment processing and achieve continuous processing.

- Maximum part spacing: 1000mm.

- Supports 54 series G code and all kinds of processing.

- Automatic Tool compensation, C tool compensation function is available.

- It has automatic chamfering and rounding functions.

- Dual channel analog output allows controlling two spindles.

System structures

32-bit high performance, low power consumption industrial grade ARM microprocessor.

64MB memory.

32Mb user storage room.

8 inch true color LCD display with 800×600 resolution

. High anti-jamming switch power.

USB input

RS232 port

Spindle servo speed control / spindle frequency conversion speed control.

Manual pulse generator.

System technical parameter

Controllable axes:X、Z

linkage axes:Arc 2 axes, liner 2 axes.

Stroke equivalent:X、Z: 0.001mm.

Max speed:X、Z: 60000mm/min.

Cutting speed:1-10000mm/min.

Min input unit:0.001mm.

program size range:±99999.999.99

tool management

Controllable liner vertical type or rotary disk type tool changer

Program code: ISO-840 international standard

Program coordinate system definition:ISO-841

Chassis protection conforms to IP43 regulation

System function

Self-diagnosis function

When the system starts or resets, all relevant diagnostics of CPU, memory, LCD, I/O interface, parameter status, coordinates, processing program, etc. will be executed. It performs real-time diagnosis of power, spindle, limit and all I/O interface during operation.

Compensation function

Automatic clearance compensation

Tool radius automatic compensation

Tool radius automatic offset and sharp angle transition

Leading screw pitch error automatic compensation

Abundant instruction system

Up/down scale instruction

Mirror processing instruction.

Multi-tool offset instruction.

Program cycle, skip, call and different program finishing

multiple positioning instruction:starting point,setting fixed point etc.

Linear, circular,spiral line interpolation instruction.

Program management instructions: program cycle, call, transfer and different program finishing method etc.

6 workpiece coordinate systems

Chinese/English menu, full screen printing

Easy to use, comfortable viewing

Abundant debugging functions

It can clearly show what processing errors are there and provide guidance for correcting them.

Program exchange between CNC system and IBM/PC series compatible computer

It can realize CAD/CAM/CAPP auxiliary programming by using abundant software resources of PC series compatible computer,then transfer CNC program to system through(USB portable U disk copy port、RS232 port)to process. You can connect it to PC from system through communication port.

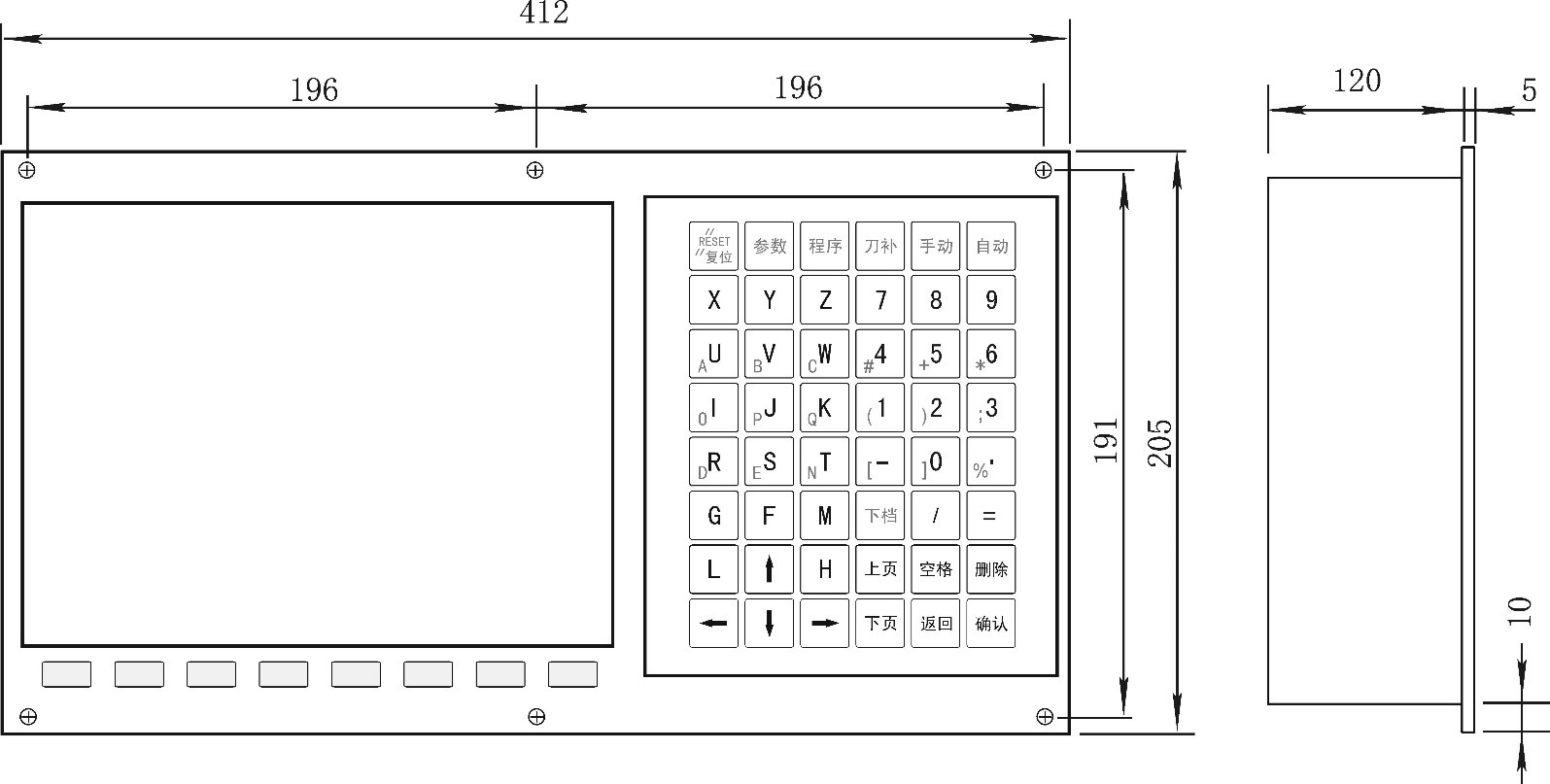

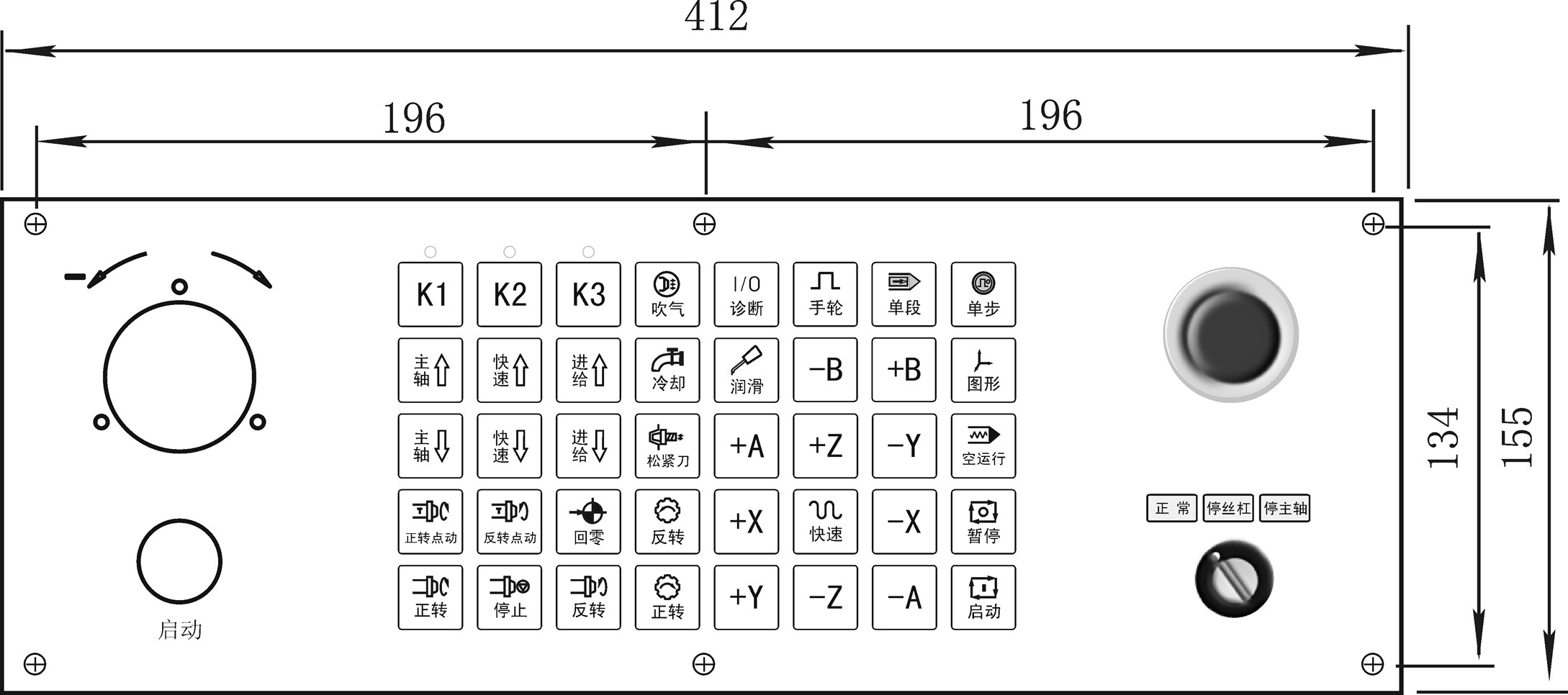

DIMENSIONS