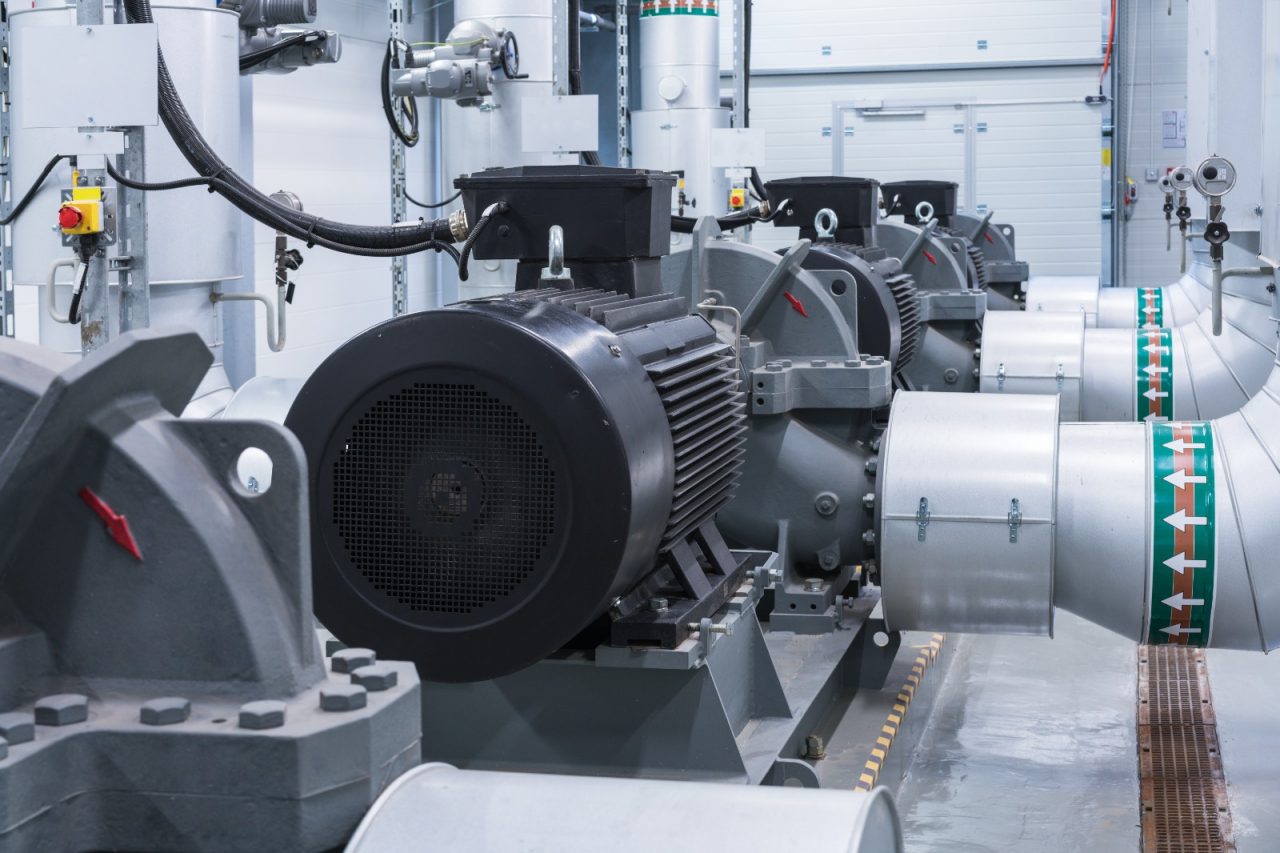

Electric motors make up about seventy percent of the electrical energy used in industry. For this reason, the correct protection of electric motors and the prevention of unplanned stops provide an increase in efficiency spread throughout the plant. Although there are no clear-cut rules in engine protection, there are basic elements to consider in engine protection. In this article, we will take a look at the common mistakes made while protecting the engine.

Incorrect Selection of Low Voltage Protection Values

Motors operating below their rated voltage may be subject to overheating and have a shorter lifespan. According to the National Electrical Manufacturers Association (NEMA), it is not recommended to run motors below 90% of their rated voltage for extended periods of time. Note that if an undervoltage protection is set too high, it may disconnect the motor when not needed.

For example, a three-phase motor with a rated voltage of 230V has 207V of the lowest acceptable operating voltage according to NEMA. However, if an adjustable Low Voltage relay is set to 220V, a voltage drop of 5% will be sufficient to disconnect the motor.

Thermal Overload Setting

The basic requirement for overload protection setting for motors is 125% of full load currents according to NEC; however, it is also necessary to consider the overload relay instructions. If the 125% value is not integrated into the relay, you should set it to +25% current on the motor nameplate.

If the overload protection is set too low, the motor may be disconnected even during normal operation. This means unnecessary downtime and the engine is not protected at the desired level. Of course, the overload protection should not be set too high either, as the motor will not be adequately protected against overload. For example, if you add 15% when setting an overload relay with a built-in value of 125%, the actual overload protection value will be 144% and this does not meet the desired standards.

Magnetic Protection Set