SR6600 is a robot specially designed for desktop picking and installation applications. Relying on the servo control technology accumulated in Huazhong CNC for many years, using self-developed control technology and making full use of the performance of the servo motor, it can carry a load of up to 6kg under high torque conditions, and the speed of the motor can reach 5000. Under the condition of high speed, the revolutions and length of the 1 and 2-axis series arms can reach 600MM. It has the advantages of high speed, high performance, high precision, small size, flexible movement and low price. The first and second axes in series are similar to the human arm, which can quickly locate and orient in the plane, and can be extended into limited space and retrieved after operation. Huashu SR6600 can be widely used in the electronic products industry, pharmaceutical industry and food industry.

It has a high cycle time.

It has excellent acceleration/deceleration, compatible soft start/stop time.

High-speed cycle time is as low as 0.4S, ensuring parts processing quickly and accurately.

It has a load carrying capacity of up to 6Kg and a nominal load carrying capacity of 2Kg. It can maintain a high cycle rate even if the load increases.

It provides precision machining, multiple machining processes and excellent assembly control.

Orbit accuracy testing is carried out using DYNALOG, an advanced measurement and calibration equipment abroad.

It has repeated positioning accuracy of 1st and 2nd joints (+0.02MM), 3rd joints (+0.01MM) and 4th joints (+0.01 degrees).

It is subjected to a stability test before leaving the factory. In order to ensure the stability of quality, a test lasting more than 7*24 hours is applied.

Rich user interfaces and internal wiring of the main body are on it. Servo motor power line and coding line are also on it. Also φ8 air pipe is on it, which not only maintains the user-friendly DB15 interface and overall appearance, but also facilitates it.

The 3-axis robot has a hollow design. Thanks to this design, the user's air pipe can pass inside the arm to reduce air friction.

Easy dragging makes teaching and positioning recording more accurate and convenient.

You can use it in common industrial applications.

Widely applicable fields: Medical drugs, laboratory automation, consumer products, industrial products, telecommunications, pharmaceuticals, packaging, semiconductor, electronics and other industries.

| Industrial Robot Model | HSR-SR6600 | |

| Number of Axis | 4 | |

| Maximum Load/ Specified Load | 6kg/2kg | |

| Maximum Working Radius | 600mm | |

| Repeatability | ±0.02mm | |

| Range of Motion | J1 | ±132° |

| J2 | ±150° | |

| J3 | 0-200mm | |

| J4 | ±360° | |

| Rated Speed | J1 | 225°/s, 3.92rad/s |

| J2 | 360°/s,6.28rad/s | |

| J3 | 666mm/s | |

| J4 | 1200°/s, 20.93rad/s | |

| Maximum Speed | J1 | 375°/s, 6.54rad/s |

| J2 | 600°/s, 10.46rad/s | |

| J3 | 1111mm/s | |

| J4 | 2000°/s, 34.88rad/s | |

| Allowable Moment of Inertia | J4 | 0.12kg㎡/0.01kg㎡ |

| Allowable Torque | J4 | 4.23Nm |

| Applicable Environment | Heat | 0~45° |

| Moisture | 20%~80% | |

| Other | Avoid contact with flammable, explosive or corrosive gases and liquids. Keep away from electronic noise sources (plasma). | |

| Control Cable Length | Option el 8m | |

| Cable Distance Between Robot and Board | 10 foot | |

| I/O Parameters | Digital: 32 inputs, 31 outputs (one for control cabinet fault indicator output) | |

| Battery Capacity | 0.8kVA | |

| Rated Power | 0.6kW | |

| Rated Voltage | Single phase AC220V | |

| Rated Current | 3.2A | |

| Protection Class | IP54 | |

| Installation Method | Floor installation, desktop installation | |

| Body Weight | 21kg | |

| Panel Protection Class | IP53 | |

| Panel Dimensions | 500(Width)×270(Thickness)×530(Height) | |

| Board Weight | 38KG | |

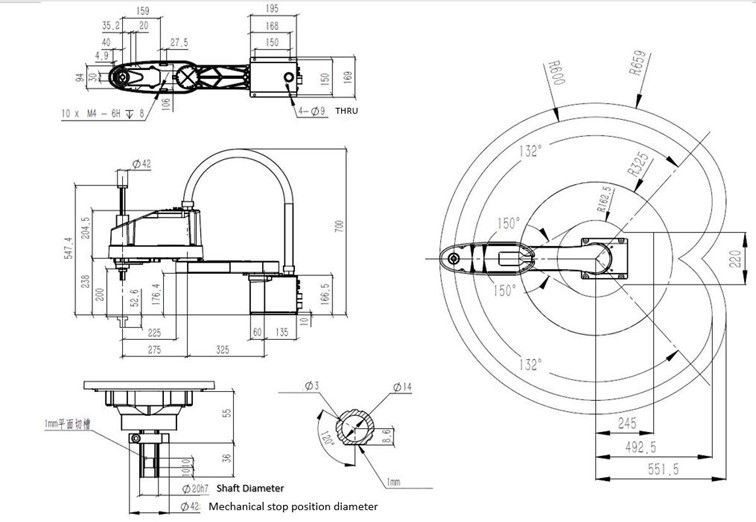

DIMENSIONS