HNC Electric 808xp-M system adopts advanced open architecture, built-in Industrial Personal Computer (IPC), 7 inch color LCD display and standard operation panel. The system integrates interfaces for feed spindle, spindle, handheld units and built-in PLC, USB application reading function, mainly suitable for numerical control milling machine. The system has the following significant advantages:

- Low cost

- High performance

- Compact structure

- Easy to use operation

- High reliability

- Maximum coordinate axes: 3 axes.

- It is compatible with various pulse command AC servo drives.

- There are 32 inputs and 24 outputs. It is configured with handwheel interface, simulation spindle control and encoder interfaces.

- 7” black and white or color LCD options are available. (Resolution: 320 x 240)

- It provides functions to identify faults, report alarms and display graphic processing paths, allowing users to easily operate and use the system.

- It supports international standard G code programming and various popular CAD/CAM automatic programming systems. It supports advanced plan editing and draft programming. It has linear, circular and thread interpolation, fixed-loop programming, rotation, image resizing, mirroring, tool compensation and customized macros.

- It supports the function for fixed small line segment machining, which is suitable for complex modules' part machining.

- Supports breakpoint saving and processing recovery functions.

- Supports backlash compensation, single or double direction step error compensation to improve machining accuracy.

- It supports USB interface to provide easy and fast data access.

- It supports Ethernet communication to ensure fast program and data transmission.

- It supports 400 KB (expandable using a CF card) Flash RAM shutdown storage and 32 MB RAM buffer.

| CNC Function | Maximum controllable axes: three feed axes and one spindle

Maximum coordinate axes: three axes |

| Minimum resolution: 1μm | |

| Automatic control of acceleration and deceleration (straight line/S curve)

Return to reference point |

|

| Setting coordinates

Graphical simulation and real-time monitoring of the machining process |

|

| Simple circular turning

Compound circular turning |

|

| CNC Programming Function

|

Minimum programming unit: 0.001 mm

Maximum programming size: 999999.999 mm |

| Maximum programming lines: 300000

Metric system/English system programming |

|

| Absolute/incremental programming

Macro instruction programming |

|

| Subprogram search

Setting workpiece coordinates |

|

| Automatic chamfering control (round angle, right angle) | |

| Interpolation function | Line interpolation for a maximum of three axes |

| Circular interpolation

Cutting by touch |

|

| Tool compensation function | Tool length compensation

Tool radius compensation |

| Working Function | 8.4 inch TFT color LCD

Anti-static electricity program and machine operation panel |

| Standard PC keyboard interface

Handwheel units (optional) |

|

| Graphic display and dynamic real-time simulation

Network communication (optional) |

|

| Feed axis function | Unconstrained axis rotation function

Maximum speed: 43000 mm/min |

| Feed rate override: 0% to 150%

Fast movement speed override: 0% to 100% |

|

| Various modes of returning to the reference point: one-way and two-way | |

| Spindle function | Spindle speed: determined by PLC programming (Maximum speed: 32000 rpm) |

| Spindle speed override: 0% to 150%

Display spindle speed and override |

|

| Variation rate and variation rate level: determined by PLC programming | |

| PLC function | Internal PLC

Standard PLC example Display PLC status |

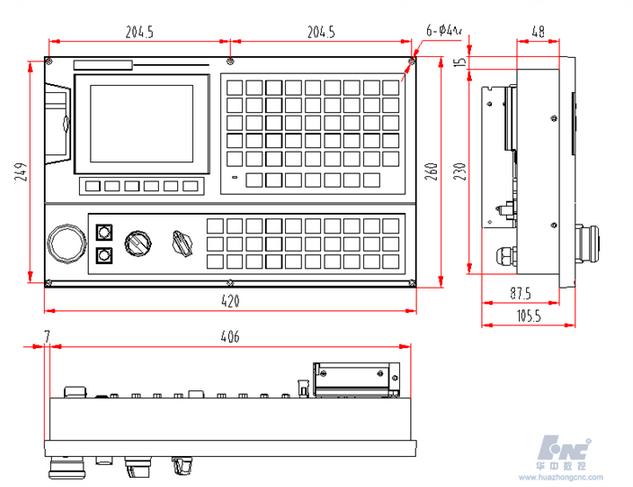

DIMENSIONS